Introduction

Marshmallows are a centuries-old sweet treat loved by children and adults alike. Once a time-consuming and laborious process, marshmallow-making has become infinitely more accessible with the new technology. The latest auto commercial marshmallow-making machines can turn this traditionally produced sweet treat into a quick and one of the most efficient ways businesses can create marshmallows. Advanced machines do everything from mixing ingredients to cutting and packaging.

They are quicker and more effective, and they always yield perfect marshmallows. Lately, we have been exploring these inspiring innovations of machines and how they streamline production. They improve business production and provide excellent solutions for businesses, be it a candy shop or high-end confectionery.

Key Features of the Latest Automatic Commercial Marshmallow-Making Machines

Advanced Automation

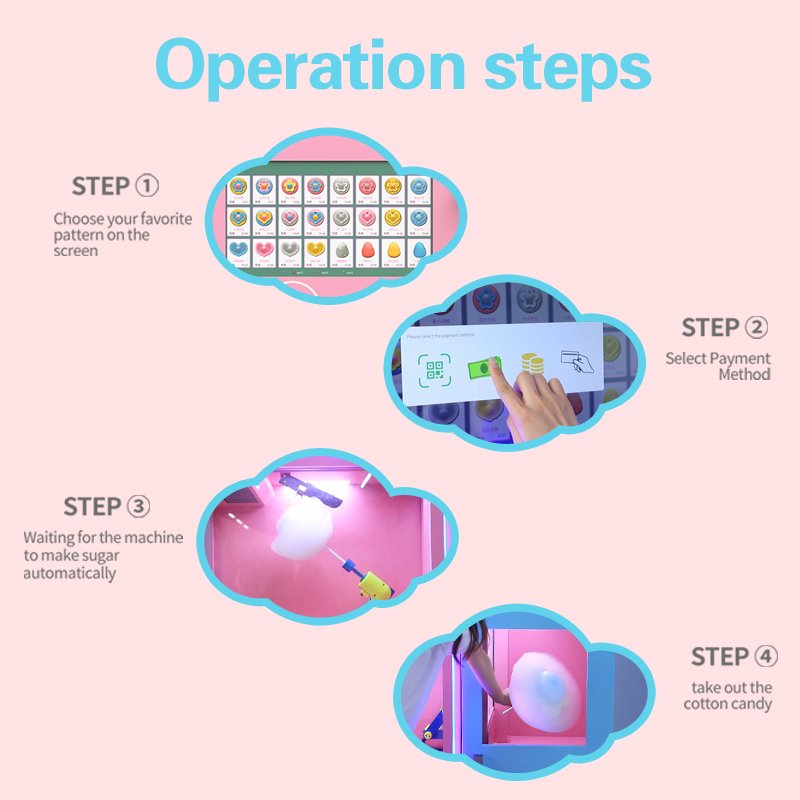

One of the standout features of the new marshmallow machines is their advanced automation. From mixing the ingredients to their cooking temperature, I poured them into molding, cut them to shape, and even packaged the marshmallows; the machine does it all. Automation at this level requires little human intervention to help drive faster production times and allow less opportunity for errors.

Precision Control

State-of-the-art commercial marshmallow-making machines are exact. These machines’ control systems set the temperature, time of mix, level of cooking, and cutting speed to an exact ‘t.’ This kind of precision reckons that together with the product’s similarity in size, texture, and flavor for every batch of marshmallows produced.

Continuously monitoring production with state-of-the-art sensors and feedback mechanisms, adjustments are made in real-time to ensure optimal conditions are met. Top-quality marshmallows come out each time this occurs.

High Capacity

The latest high-capacity output machines are available for commercial production. They can churn out thousands of marshmallows per hour, making them imperative in businesses where orders run into bulk quantities.

High-capacity machines will help the business meet market demand without compromising the quality of the product. They are designed for bulk handling efficiently without requiring multiple machines and consuming valuable floor space in your production facility.

Versatility

Another fabulous feature of these machines is their versatility. They can make marshmallows in different shapes, sizes, and flavors. This is possible due to the availability of changeable molds and programmable settings that allow for easy switching between products and minimal time loss.

This will be very instrumental, especially for businesses that would like to offer their clients various types of marshmallow products. It provides room for creativity and product innovations, giving the company a niche in the market.

Energy Efficiency

Energy efficiency is considered in today’s manufacturing. These new machines were developed to make marshmallows take great care of energy consumption. Advanced technologies installed within the machines aim to reduce wastefulness and work smart in their power usage, thus having a cost-effective impact on businesses and the environment.

It lowers energy consumption, decreases operational costs and the carbon footprint, and aligns with increased demands on sustainable business.

Efficiency and Productivity Improvements

Reduced Labor

Among the more prominent advantages of state-of-the-art commercial marshmallow-making machines is a drastic reduction in labor. Conventionally, several steps go into making marshmallows that require some expert workers; these machines, however, are highly advanced and automate the entire process.

Automation requires less workforce to monitor the production process and minimizes labor costs and the occurrence of human error. Consequently, this will offer marshmallows that are of better quality and more consistent.

Faster Production

These machines are designed to work quickly. They understand the mixing, cooking, formation, and cutting of marshmallows at higher speeds than by hand. The increased speed allows large quantities to be created within a concise time frame, satisfying demand efficiently. Therefore, faster production for a business receiving volume orders or having tight deadlines is essential in establishing a solid competitive edge.

Consistency

It is about the uniformity in product quality that flourishes within the confectionery industry. Automatic machines ensure every marshmallow is nice and well done, batch after batch. Inherent in these accurate control systems are minute adjustments taken in real time to maintain the best conditions within the boundaries of production procedures. This helps reduce flaws and produce more satisfactory customer products, creating or strengthening brand image.

Minimal Downtime

Newer machines are more reliable and easier to maintain. Quick-change components and accessible interfaces facilitate quick adjustments and troubleshooting. Regular maintenance schedules can be easily followed, significantly reducing the probability of unexpected breakdowns. This focus on minimizing downtown ensures continuous production and maximum output that keeps any business running smoothly and efficiently.

Benefits Over Traditional Methods

Time-Saving

Traditionally, making marshmallows can be time-consuming. The process undergoes various stages, and each needs to be carried out one after the other. The invention of automatic commercial marshmallow-making machines has drastically reduced the time required for each process. This machine automates mixing, cooking, forming, and cutting, doing all these quickly, which helps the business produce more marshmallows quickly.

Labor Costs

Advanced automation of marshmallow-making significantly reduces the requirement for Manpower. Traditional methods require many skilled workers to handle different stages of production, from mixing to packaging. With automated machines, fewer employees are needed to monitor and manage the process, which can result in substantial labor savings. This reduction in labor also minimizes the potential human error factor, hence consistently producing fine quality.

Quality Control

The computerized, advanced quality control features of automated commercial marshmallow-making machines ensure that every marshmallow rolled out of the production line is of a high standard.

The production process, monitored by sensors and controlled by control systems, adjusts on the fly for consistency in quality, reducing defects/wastes and resulting in better yields and profitability. High-quality products bring a strong brand image to customers and ensure customer loyalty.

Scalability

One of the most essential benefits that automated commercial marshmallow-making machines can offer growing businesses is scalability. Such machines will scale production in times of rising demand without causing a proportionate increase in labor or operational complexity. This scalability enables business growth and adaptability to new market conditions by helping to enter new markets and cater to larger volumes of customers.

Success Stories and Case Studies

Case Study 1: Sweet Delights Confectionery

Mid-sized candy manufacturer Sweet Delights Confectionery had likewise invested in a state-of-the-art automatic marshmallow-making machine to improve its production capability. In just the first six months, it saw a 40% increase in output and a 30% decrease in labor costs.

Precision controls on their new machine resulted in less product variation, decreased quality problems, and increased customer satisfaction. This enabled Sweet Delights to cater to the ever-growing demand and increase their variety.

Case Study 2: CandyCo Enterprises

Enterprises are one of the large-scale confectionery producers. They introduced state-of-the-art commercial marshmallow-making machines into their production line. Now, they can produce featured marshmallows with complicated designs and flavors, which are often deemed impossible to produce using the traditional manual techniques of yesteryear.

By doing this, CandyCo increased its market share by 25%, serving new territories. Their versatility and high capacity allowed machines to scale up production, effortlessly meeting large and small orders.

Buying Considerations

Assessing Production Needs

Before buying an automatic marshmallow-making machine, you should consider your production needs. You should know the volume, diversities, and growth projections you wish to achieve. It is very important to match the current needs by picking a machine that offers great alignment yet flexibility so that it grows with your business—so that investment doesn’t go to waste.

Budget and ROI

The cost of the machine has to be judged against what it is likely to bring in by way of ROI. While high-tech machines are expensive up front, significant long-term savings in labor costs and energy consumption and augmented efficiency in production make up for the outlay. One shall calculate payback time and total financial effect to arrive at any decision. Ensure that the chosen machine offers the best cost-performance ratio.

Features and Customization

Know whether features and customization options meet your needs. Consider the features that define the machine’s efficiency regarding production speed, capacity, energy efficiency, and ease of maintenance.

Machines with modular designs or custom parts have added flexibility and adaptability. This lets you get a more fine-tuned feel for the kind of machine you mean for your exact production conditions and quickly respond to changes in demand or product lines.

Supplier Support

The very essence of this factor is the supplier’s reliability and the support he provides. The supplier should be reliable and must provide good after-sales support regarding training, maintenance, and technical assistance.

A good warranty and service agreement can provide great peace of mind and ensure the smooth running of everything. Reliable supplier support prompts the rectification of any problem and ensures there is no stop-line in the production line.

Conclusion

The latest innovations in commercial marshmallow-making machines have revolutionized the confectionery industry. With advanced automation, precise control, high capacity, versatility, and energy efficiency, these machines offer numerous advantages over traditional methods. They save time, reduce labor costs, ensure consistent quality, and allow scalability. Real-world success stories from companies like Sweet Delights Confectionery and CandyCo Enterprises highlight the positive impact of these machines on productivity and market expansion.

Investing in the latest automatic commercial marshmallow-making machines is a smart move for businesses looking to stay competitive and meet growing demand. These state-of-the-art machines enhance efficiency and product quality and support sustainable business practices. Embrace the future of marshmallow production and watch your business thrive with these innovative machines.

Call to Action

Ready to revolutionize your marshmallow production? Invest in the latest automatic marshmallow-making machine from Chituvem and boost your efficiency, quality, and profitability. Don’t miss out on this game-changing opportunity – visit Chituvem’s product page and upgrade your business today!